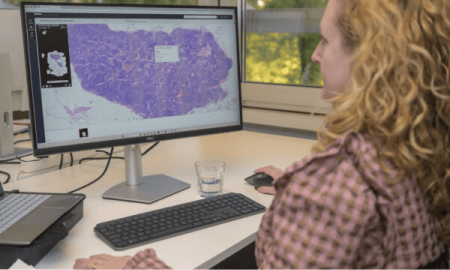

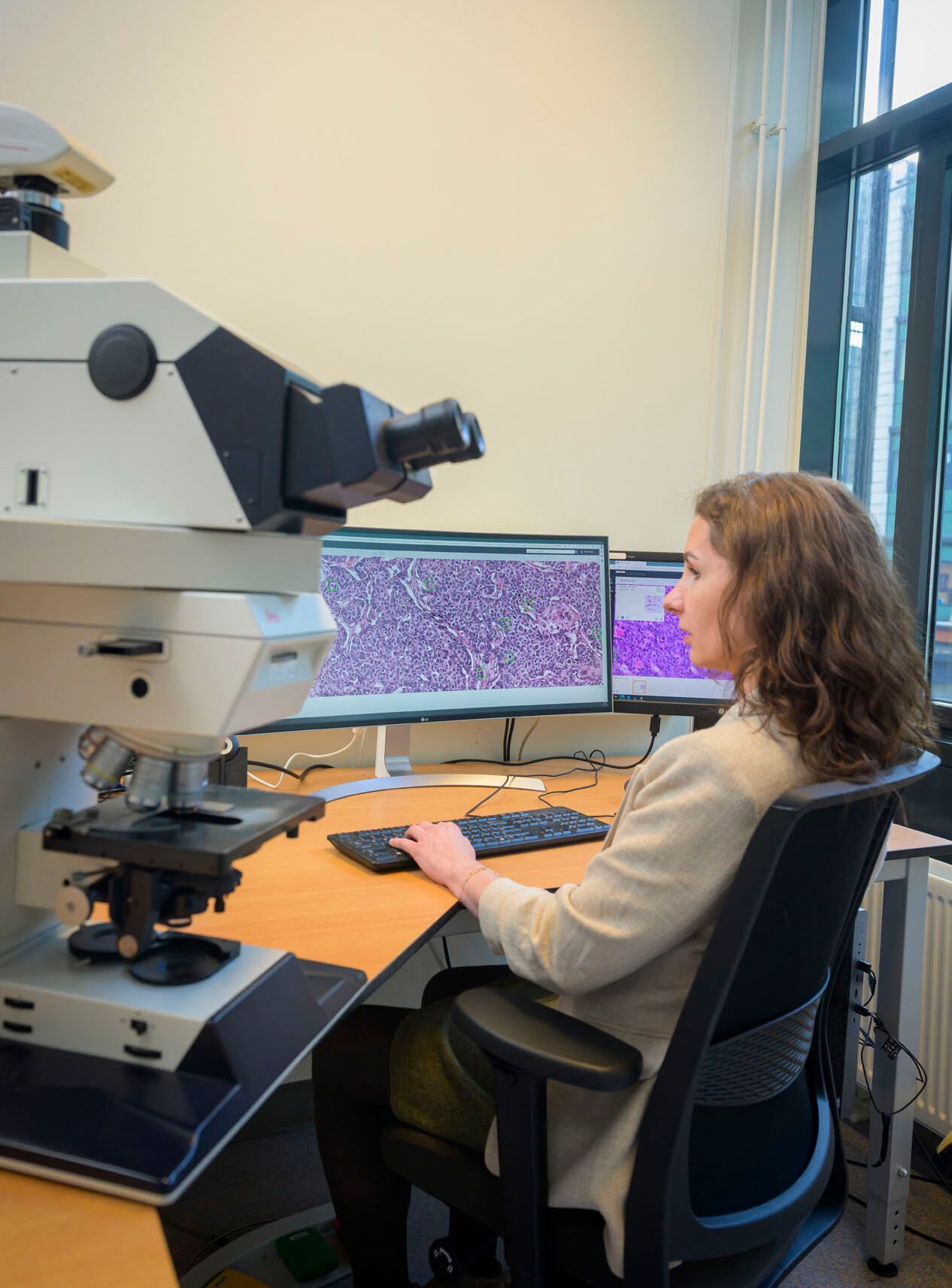

In the field of digital pathology, the introduction of whole slide images (WSIs) has brought both benefits and challenges. The primary advantage of transitioning to a digital workflow lies in the availability of high-resolution WSIs that can be accessed and analyzed digitally. This breakthrough opens numerous doors, enabling remote inspections and seamless sharing and collaboration with colleagues. Additionally, digital slides can be more easily stored, retrieved, and tracked, facilitating accessibility for future reference.

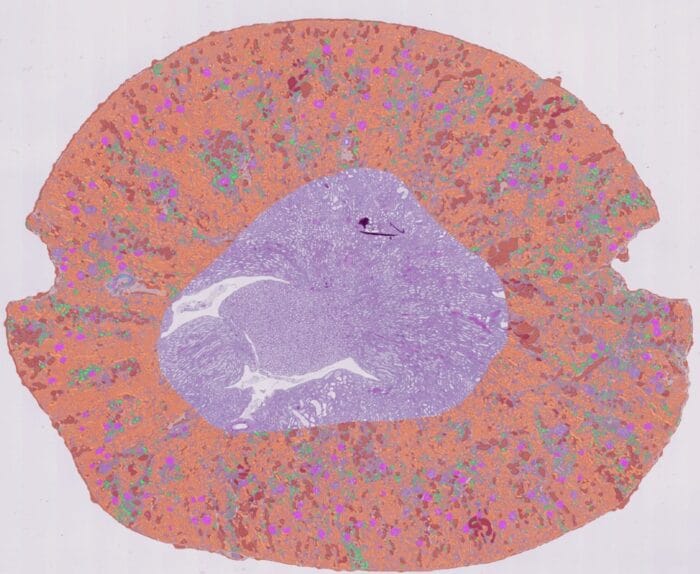

One pressing concern revolves around artifacts that often plague these images, significantly restraining workflow efficiency. The slide preparation process can give rise to a range of artifacts, including tissue folds and air bubbles. Additionally, scanning procedures may also compromise the quality of WSIs, for instance with out-of-focus areas. These quality artifacts make the sample analysis more difficult since some regions become unreadable. When these issues are detected, the samples need to be rescanned and sometimes preparing new histology slides is also required.

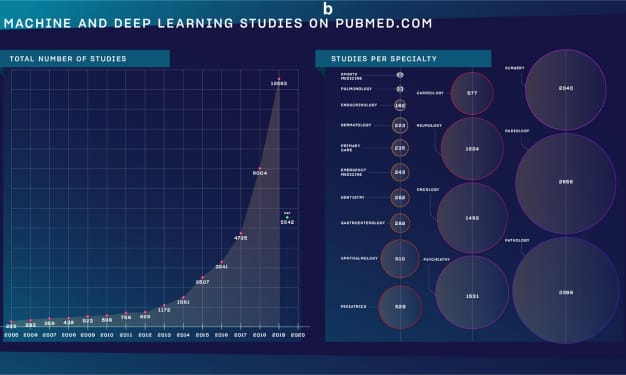

Detecting and addressing artifacts early on is crucial to ensure high-quality whole slide images, which are essential for accurate diagnoses in clinical and research settings. A future where pathology workflows are not burdened by the late detection of these anomalies is on the verge of becoming a reality as evolving technologies automate the once laborious manual quality control (QC) tasks. This article explores how automated quality control algorithms, driven by deep learning machines, have the potential to significantly accelerate pathology workflows.

The challenges of manual whole slide inspection

Before pathologists proceed to review digital slides, it is essential to ensure that images meet high-quality standards. The key challenges in quality assessment include time consumption, lack of standardization, and late detection.

Time-consuming visual inspection

Traditional visual inspection is a time-consuming process, as some artifacts may not be readily apparent to the naked eye at low magnification. Laboratory technicians must invest additional time to thoroughly examine the slides and ensure comprehensive inspection of the images. As the number of digital slides increases, pathology laboratories face the overwhelming task of manually reviewing each image, which can significantly prolong the diagnosis process. The lack of timely detection can have serious consequences, as it may lead to delayed diagnoses, treatment, and compromised patient outcomes.

Lack of standardization

The identification of digital slides compromised by the presence of artifacts, such as tissue folds or air bubbles, is a subjective task since it is manually performed. Traditional visual inspection methods often lead to significant variations between slides that are accepted and those that require further review, owing to the natural variability among individuals. For instance, some technicians may decide to ignore smaller or medium artifacts while others might consider they are large enough to compromise readability. Therefore, the integration of AI-driven quality control systems enables the establishment of standards for acceptable slide quality.

Delayed artifact detection

Late detection of artifacts in whole slide images can have detrimental effects on the accuracy and reliability of diagnostic and research results. Artifacts that go unnoticed or are detected at a later stage can also lead to delays in diagnosis and treatment, potentially compromising patient outcomes. Additionally, delayed artifact detection can result in wasted time and resources as pathologists may need to revisit previously analysed slides or acquire new ones. Therefore, timely identification and mitigation of artifacts in whole slide images are crucial to ensure the integrity and effectiveness of the diagnostic and research processes.

Optimize your workflow with an AI-powered quality control step

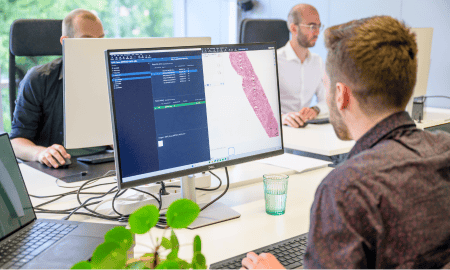

To fully comprehend the efficiency gains brought by the automation of the quality control of WSIs, it is important to understand the algorithm’s implementation in the workflow.

The process of automating QC follows a systematic approach:

1. Slides are prepared and uploaded into the digital platform as usual.

2. Machine learning algorithms thoroughly inspect the images before these are opened for review.

3. If no issues are detected, pathologists can proceed with the analysis.

4. In the case of artifact identification, they are flagged for further evaluation. Pathology laboratories may define specific thresholds to determine compromised images.

Implementing an automated quality control system helps laboratories to ensure timely detection of artifacts, enhancing overall efficiency and offering benefits such as reduced material usage, cost savings, and accelerated diagnosis. This approach eliminates time-consuming steps, freeing up valuable time for critical tasks. In addition to streamlining diagnostics, immediate artifact identification with QC algorithms can also improve research workflows, saving resources, and enabling consistent quality control. Standardized processes improve current research efficiency and contribute to reliable data accumulation, facilitating result comparison and interpretation. Therefore, with the implementation of automated quality control systems, both research and diagnostics laboratories can enhance their workflow, driving innovation and improving patient care.

Learn more

Explore how AiosynQC can improve the efficiency of your laboratory. Find additional information regarding our AI-powered quality control solution, examples of artifact detection, integration, FAQs, and more.

More Blogs

-

AI assistance in Chronic Kidney Disease monitoring

03 July, 2024 • By Kama Witkowska

Read more -

Behind the scenes of pathology AI innovation – Blazej Dolicki’s insights into training, validation, deployment, and beyond

18 June, 2024 • By Victoria Grosu

Read more -

A short overview of the history of pathology: origins, early days, and the transition to novel technologies

16 May, 2024 • By Kama Witkowska

Read more -

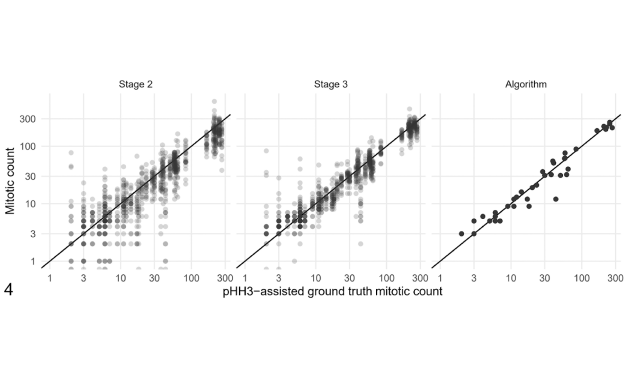

The benefits of AI implementation in mitotic figure counting

11 April, 2024 • By Kama Witkowska

Read more -

Diana Rosentul explains the complexities of regulatory compliance for integrating AI-based solutions in the healthcare industry

25 January, 2024 • By Diana Rosentul

Read more -

Cristina González Gonzalo discusses her journey with the clinical validation of Aiosyn Mitosis Breast

14 December, 2023 • By Anna Correas Grifoll

Read more -

Time to go digital? Navigating the pathology transition from microscopes to whole slide images

30 November, 2023 • By Victoria Grosu

Read more -

Prepare for the future: AI is changing the landscape of pathology

09 October, 2023 • By Victoria Grosu

Read more